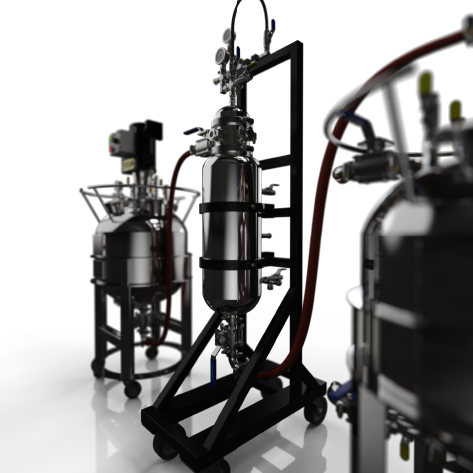

TITAN Dewax

The TITAN Dewax System is purpose-built for operators focused on dewaxing, winterization, and advanced hydrocarbon isolation processes. Designed on the TITAN series platform, it features jacketed columns, optimized flow paths, and a fully modular rack-mounted system engineered for maximum efficiency, faster recovery, and consistent high-purity results.

Built to plug straight into the TITAN ecosystem, the TITAN DEWAX delivers a clean, repeatable dewaxing step that pairs seamlessly with upstream extraction and downstream post-processing for faster, more consistent throughput. Available now in a 5-liter configuration, the DEWAX line will expand with a 10-liter model arriving in early 2026 for labs ready to scale.

• Clarify High Terpene Extracts (HTE)

• Complete the TITAN series workflow

• Compatible with ANY other machine out side of the TITAN series

• Requires zero powders/granular media

• ASME-Certified Components: Ensures safety, durability, and pressure compliance to industry standards

• Compact and Modular Design: Space-saving footprint with scalable configuration for future expansion

• 30 Minute Run Times: Keep your lab efficient with fast processing speeds

*Dependent on chiller specifications

• Process 5 Liters HTE at once

• Dewax virgin extract or extract devalued by wax content

Footprint: 100”x 76” x 35”

HTE processed/ hr: 10 Liters

Technicians recommended: 1

Column Size: 6”x24” Double Jacketed

Recommended Heater: 24kW

Recommended Chiller: -50°C

Approx L produced/ 8hr shift *Dependent on chiller spec.: 15-25L